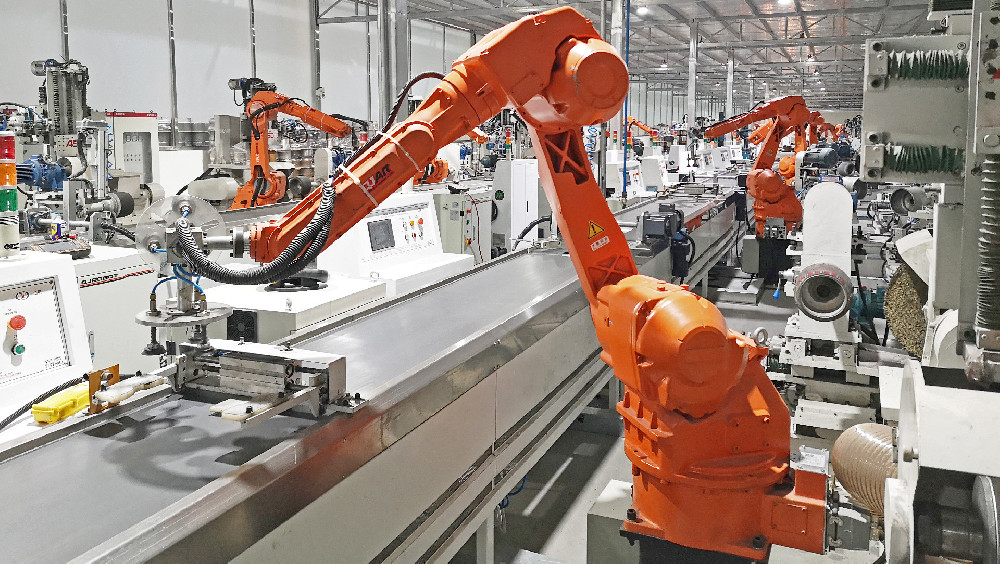

机器人码垛系统是专业的自动化搬运码垛设备,替代人工将不同形状尺寸的包装货物,整齐、自动地码在托盘上或生产线上等,

可全天候作业,能迅速提高生产效率和产量,同时能减少人工搬运造成的出错。

应用行业:饮料、乳业、食品、啤酒、石化、药品等生产线的搬运、拆装、摆放等方面;物流行业的装箱与卸载等方面;尤其

是在箱子、袋类装载货物以及较为规则的批量生产线上。

产品优势:速度快,效率高,节省人工,占地空间小,操作方便,适用性强,能耗低。

The robot palletizing system is an automatic palletizing equipment. It replaces manual packing of goods of different shapes and sizes, automatic coding on the pallet or production line, non-stop operation, can quickly improve the efficiency of production and output, and reduce the errors caused by manual handling. Application

scope: dairy, beverage, food, beer, petrochemical, pharmaceutical production line handling, disassembly,

placement and other aspects of the logistics industry; loading and unloading etc.; especially the mass production line of loading goods into boxes, bags, and other high volume production lines.

Application Field:Dairy, beverage, food, beer, petrochemical and pharmaceutical production line handling, disassembly, placement, and other aspects of logistics industry; loading and unloading etc; especially the mass production line of

loading goods into boxes, bags, and other high volume production lines.

Advantages: High speed, high efficiency, labor saving, small space occupation, easy operation, flexible, low energy consumption.

视频中案例实现猪饲料码垛,速度每小时600包

型号:QJRB20-1、QJR6S-1、QJRB180-1 应用行业:炊具

型号:QJRB800-1 应用行业:建材

型号:QJRB180-1 应用行业:炊具

型号:QJRB20-1、QJR6S-1、QJRB180-1 应用行业:炊具

型号:QJRB20-1/QJR6S-1/QJRB180-1 应用行业:炊具